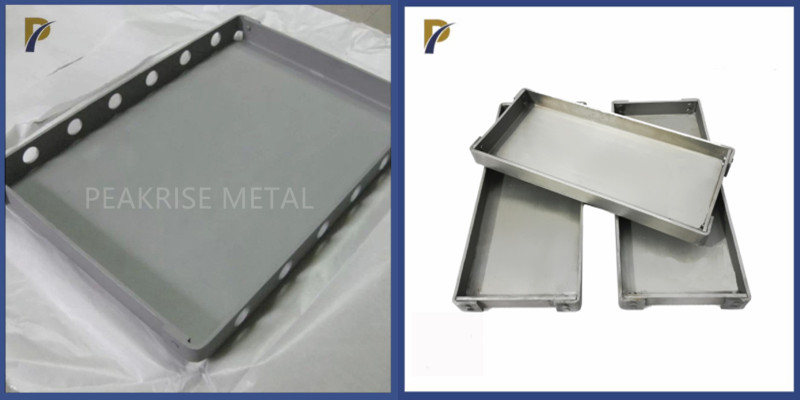

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced

tungsten,molybdenum, tantalum, niobium, titanium,zirconium,nickel

non-ferrous metal production enterprise,main products include

tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum

alloy, high specific gravity tungsten alloy, tantalum alloy,niobium

alloy,titanium alloy and other more than 100 kinds of products.In

2010, with the surge in export sales of products in this industry,

we began to focus on foreign trade export business,provide

high-quality non-ferrous metal products for the international

market.After years of development,at present, it has become a

comprehensive non-ferrous metal production enterprise integrating

manufacturing and processing, material research and development,

product testing, and stock inventory.The development of nearly ten

years reminds us that high-quality products and services are always

our top priority,at the same time, we continue to expand into new

fields and provide high-quality products and services for more

domestic and global customers.Products are exported to Taiwan,

Ukraine, South Korea, the United States, Australia, Germany, Iran

and other countries, and have established long-term good

cooperative relations with customers. Our products are highly

recognized and evaluated by customers.

Peakrise Metal has a variety of production equipment, such as

intermediate frequency sintering furnace, vacuum arc melting

furnace, laser cutter,plasma electron beam melting furnace, vacuum

annealing furnace, various rolling mills, wire drawing machines,

plasma welding rooms, lathes, milling machines, sawing machines,

drilling machines, Shears, Stamping Equipment, Cutting Equipment,

Grinders, Straightening Machines, CNC, etc.

Five Reasons To Choose Us

1. Rich production and export experience

Our company specializes in the R&D, production and processing

of tungsten, molybdenum, tungsten copper, molybdenum copper and

their alloy materials. In terms of metal deep processing, we have

more than 13 years of rich production experience and export

experience, and solve related import and export problems for

customers. , one-stop solution to all difficulties.

2. Low factory price

We have our own factory and long-term stable manufacturers, we can

provide customers with high-quality products at extremely low

ex-factory prices. If you are interested in our products, please

feel free to contact us. We are confident that you will enjoy all

quality products at wholesale prices.

3. Quality Assurance

The company has established a complete quality assurance system

based on the ISO9001 standard, and is equipped with advanced

testing instruments, adopting international unified testing

standards; and in order to ensure the traceability of each batch of

products, we will establish documents for each batch of products,

recording from production, The whole process from shipment to

customer feedback, thus improving product quality and customer

satisfaction.

4. Fast Shipping/Professional Packing

Through long-term partnerships with UPS, FedEx, DHL and other

leading global carriers, we are able to provide world-class

shipping options. Your products will be carefully inspected and

safely packed before dispatch. To ensure that we always provide you

with the highest level of service.

5. Best Customer Service

We value our relationship with every customer, so our professional

customer service team is always here to help. Always take quality

and service as our responsibility, and always cooperate with

customers with professional technology and integrity. Customer

satisfaction is our eternal purpose, we provide first-class service

to make customers fully satisfied.